Magnesium piston technology: lightweight material offers improved performance

A special lightweight magnesium alloy for pistons from STIHL means enhanced performance for professional chainsaw operators.

12.09.2024

The piston: the beating heart of the engine

STIHL chainsaws use 2-stroke engines which, like all engines, contain a piston. The motion of the piston is transferred to the crankshaft, which in turn drives the saw chain. The piston is a central components of the engine and it moves at high speed – depending on the type of chainsaw, it could reach as many as 14,000 revolutions per minute. The piston moves continuously and rapidly inside the engine cylinder, exposing the component – which is critical to the performance of the chainsaw – to high temperatures and stresses. Chainsaw pistons are not routinely serviced or replaced, which means they need to work effectively throughout the lifespan of the chainsaw, so they are manufactured to be both resilient and lightweight.

Most chainsaw engine pistons are made from aluminium – a tried and tested material which guarantees a long service life. But what if there were an even lighter material which could achieve an equally high maximum rotation speed? Our development work in this area has led us to create a chainsaw which is not significantly lighter overall, but does have a substantially enhanced power-to-weight ratio. In other words, we have launched an innovative product on the market which has harnessed the weight difference to improve performance.

Magnesium piston: lightweight construction for a powerful device

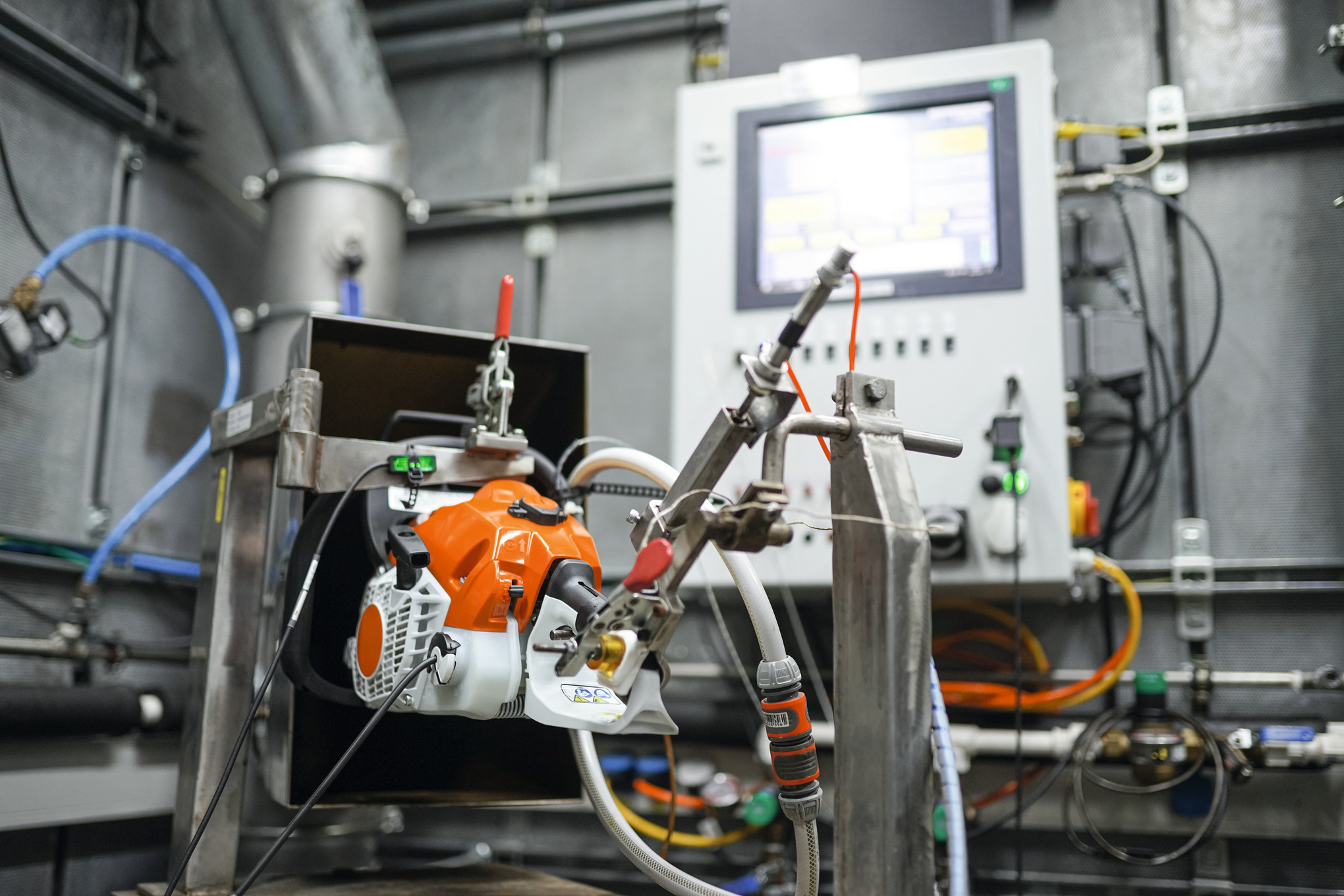

As a technology development pioneer, we have long been dedicated to the task of creating a chainsaw with lightweight components. The result is a piston made from a special magnesium alloy, manufactured under exacting supervision in our own magnesium die-cast plant. Our magnesium piston weighs less than a piston made of aluminium, but achieves an even higher maximum rotation speed. Which means improved performance, a better power-to-weight ratio and reduced transmission of vibrations to the machine operator.

To make a component which can satisfy even the most demanding requirements, we produce the magnesium piston using a special die-cast process. The piston is then hardened by means of electrolysis, a chemical process which toughens the piston surface and renders it resistant to corrosion. These advanced processes produce a piston which is particularly suitable for chainsaws used in professional forestry applications, as the advantages of the new magnesium technology can exploited to the full in challenging tasks.

There is currently one machine available with the new magnesium piston: the STIHL MS 400 C-M.

In practice, this means increased convenience together with higher performance and no loss of durability. The MS 400 C-M is a powerful device with lightweight construction, which offers excellent performance and is perfect for challenging forestry tasks such as delimbing.

STIHL MS 400 C-M for professional users: chainsaw with magnesium piston for improved performance

STIHL MS 400 C-M in comparison

| MS 400 C-M | MS 362 C-M | MS 462 C-M | |

|---|---|---|---|

| Weight | 5,8 kg | 5,6 kg | 6 kg |

| Performance |

4,0 kW | 3,5 kW | 4,4 kW |

| Power-to-weight ratio | 1,45 kg/kW | 1,6 kg/kW | 1,4 kg/kW |

Summary: magnesium piston technology

- The piston is the beating heart of the engine: its motion is transferred to the crankshaft, which then drives the saw chain

- Pistons are exposed to high stresses, which is why only a few materials are appropriate for them

- Most chainsaw engine pistons are made of aluminium

- With the MS 400 C-M, STIHL is bringing to market the first chainsaw in the world to feature a magnesium piston

- The special magnesium alloy is lighter than an aluminium piston, but equally temperature-stable

- The magnesium piston achieves a higher maximum rotation speed for improved performance